While it might be thought that the techniques for positioning that were used in the early days can still be used, the fact should be kept in mind that new devices have been developed that have totally eliminated the disadvantages for those early techniques.

What Is a Positioning Device?

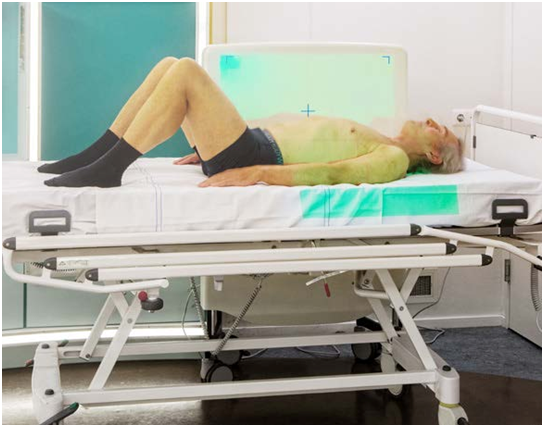

Before we could plunge into knowing the parameters which we talked about, let us first know in true terms what really a positioning device is and what it is used for. A positioning device in oncology is anything that can help the oncologist in maintaining a firm and steady position of his or her patient during treatment.These devices are needed in order to fix the patient in the appropriate position so that there is no radiation leakage to any healthy visceral parts. Too often, positioning errors pose great dangers not for the patient only, but also for the oncologist or radiologist who is carrying out the radiation session. Thus, with the help of positioning devices, these errors can be mitigated to a greater level.

The Need for Positioning Devices

As we have explained the main objective of the immobilization devices, let us see what other needs call for the installation of these devices.- Patient’s Fear

- Daily Set Up Time

- Making a Body Part Rigid

What should you look for immobilization devices?

In order to buy immobilization devices that can target cancer cells effectively, there is a need to pay heed to the following characteristics.- The device should be easy in usage and construction

- Patient should not experience any discomfort

- The device should be appropriately structured according to the body type of the patient and his or her external contours

- It shouldn’t come in the way of the radiation beam

- It shouldn’t change shape over time

- It should position the patient optimally

- The material with which it is made

- Its ability to be reused

Learn more about Radparts and the variety of services and parts they offer to repair medical equipment including: linear accelerators parts, CT scanners parts, linac parts, and radiation oncology equipment at www.radparts.com. To contact one of our medical equipment repair specialists for parts or service call toll free 877.704.3838 for 24/7/365 support.

Please take a moment to visit our

Please take a moment to visit our